To obtain correct analytical results, it is necessary to select properly samples and prepare them for analysis. Samples are selected by the Customer.

If desired, the Customer informs the Laboratory of the chosen sample preparation scheme. If there is no such a scheme at the Laboratory, we offer our own scheme in accordance with OST 41-08-249-85 and follow it agreement with the Customer.

Main sample preparation activities performed at the Laboratory are:

All samples received by the Laboratory are divided into 4 main types:

For the preparation of samples of each of the above types, there is separate room with equipment necessary for the entire technological cycle, i.e. sorting out, crushing, grinding, reduction, etc. Thus, samples of these four types are reliably isolated from one another in the process of preparation for analysis that excludes the possibility of their mutual contamination. To prevent the contamination of the subsequent sample from the previous one for each type of samples, following procedures are envisaged:

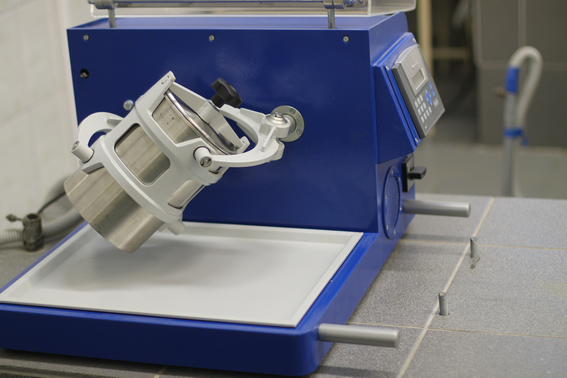

The Laboratory has the following equipment for sample preparation:

|

Item |

Manufacturer |

Maximum size of the loaded material |

Minimum final grinding |

Mill sets |

Purpose |

|

Roll-jaw crushers ВВ 400 |

Retsch, Germany |

Up to 50 mm |

Less than 3 mm |

Manganese steel |

Crushing of hard, brittle, hard-viscous materials |

|

Roll-jaw crushers ВВ 300 |

Retsch, Germany |

Up to 150 mm |

Less than 5 mm |

Manganese steel |

Crushing of hard, brittle, hard-viscous materials |

|

Roll-jaw crushers ВВ 200 |

Retsch, Germany |

40-50 mm |

About 2 mm |

Manganese steel |

Crushing of hard, brittle, hard-viscous materials |

|

Roll-jaw crushers ВВ 100 |

Retsch, Germany |

30-40 mm |

About 1 mm |

Manganese steel |

Crushing of hard, brittle, hard-viscous materials |

|

Roll-jaw crushers SHCHD-10 |

OOO Vibrotekhnik, Russia |

Up to 150 mm |

Less than 5 mm |

Manganese steel |

Crushing of hard, brittle, hard-viscous materials |

|

Roll-jaw crushers SHCHD-6 |

OOO Vibrotekhnik, Russia |

Up to 60 mm |

Less than 3 mm |

Manganese steel |

Crushing of hard, brittle, hard-viscous materials |

|

Roll-jaw crushers DSHCH-60х100 |

OOO Mekhanobrtekhnika, Russia |

Up to 50 mm |

Less than 3 mm |

Manganese steel |

Crushing of hard, brittle, hard-viscous materials |

|

Roll-jaw crushers DSHCH-80х150 |

OOO Mekhanobrtekhnika, Russia |

Up to 80 mm |

Less than 5 mm |

Manganese steel |

Crushing of hard, brittle, hard-viscous materials |

|

Planetary-type sample grinder РМ 400 |

Retsch, Germany |

Up to 5 mm |

10-100 µm |

Agate, silicon nitride |

Grinding of hard, brittle, fibrous materials |

|

Sample Grinder SM 2000 |

Retsch, Germany |

80-60 мм, |

1-20 mm |

Stainless steel, heavy metal free |

Crushing of soft fibrous and volume material |

|

Centrifugal mill ZM 100 |

Retsch, Germany |

10 mm |

0.1-1 mm |

Stainless steel, heavy metal free |

Crushing of medium-hard materials |

|

Micromill MS 100 |

Retsch, Germany |

4 mm |

Up to 10 µm |

Agate, boron carbide |

Grinding of small sub-samples |

|

Planetary mill MPL-1 |

OAO Disintegration Technology and technical devices, Russia |

2-5 mm |

Up to 100 µm |

Agate, corundum, stainless steel, rough steel |

Fine grinding of hard, brittle fibrous materials |

|

Attrition mill LDI |

ОАО Grant, Russia |

2 mm |

70 µm; 0.1 mm |

Carbon silicide |

Grinding of hard, brittle materials |

In addition, there is the AS-200 sieving machine with a set of test sieves (from 25 mm to 20 μm) from Retsch, as well as a universal bath for cleaning the sieves (fast, efficient and gentle cleaning) and racks (the same company) for gentle storage of the sieves both in vertically and horizontally.